─ OUR SERVICES

Toolmaker Mold BuildingInjection

Our molds and molded parts widely apply to various industries, like Automotive, Medical and Health care, Industrial, Agricultural, Home appliance, Electronics, Smart phones, Wearable devices, Telecommunication Equipments and etc.

OUR SERVICES

EngineeringWith over two decades of service in the mold industry, CY Mold Tech’s seasoned engineering team, through years of dedication, is committed to serving our clients. Leveraging professional DFM (Design for Manufacturing) analysis, we optimize products, streamline mold structures, and reduce mold costs.

OUR SERVICES

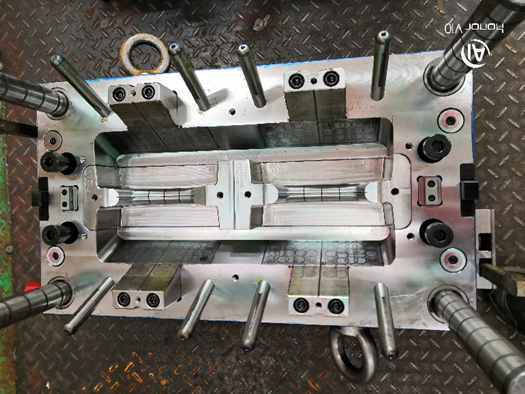

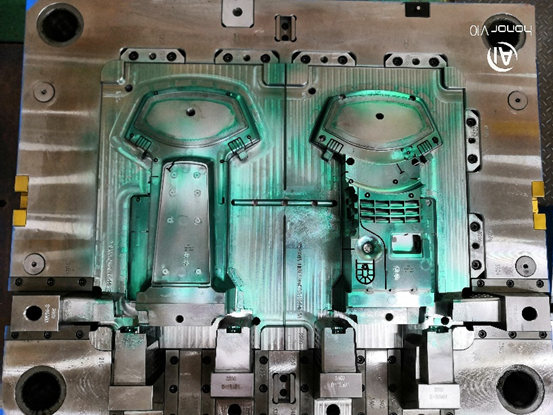

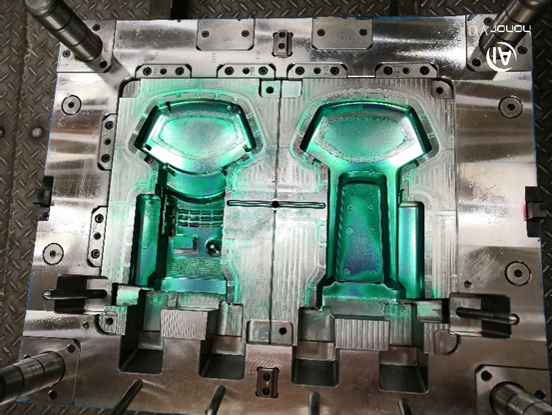

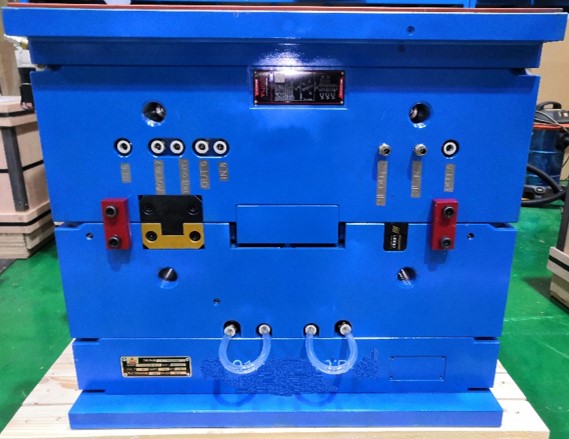

Injection MoldAdhering to customers’ mold standards, technical requirements, and product characteristics, our tooling technology team prepares DFM reports to enhance product designs, simplify mold structures, and economize on mold costs. They scrutinize the rationality of mold designs concerning client-specific injection machine compatibility, including aspects like plate thickness, machining process optimization.

OUR SERVICES

Trail out –SPIEmploying scientific injection molding methodologies, we validate the stability and reliability of molds. Trials are conducted adhering to material property sheets, with customer standards guiding the inspection and acceptance process. We optimize injection molding cycle times, ensuring appropriate holding pressure durations and cooling times.

OUR SERVICES

Precision ComponentsIn line with customer mold standards, material properties, and the unique features of mold structures, each component necessitates its tailored machining process. To ascertain the precision of these processes, our process engineers assume responsibility for every part’s machining methodology, creating process sheets for each and overseeing production until completion.

─ Our Industries

We always focus on quality and customer’s satisfaction

Automotive

Medical

Electronics

Industrial

Appliances

─ About Us

Cymoldtech Mold CO., Limited

CY Mold Tech was established in Bao’an, Shenzhen in 2009, specializing in the study and standardization, intelligentization, simplification, and enhanced efficiency of various types of injection molding dies. In order to meet the diverse needs of our global clientele and showcase the expertise of CY Mold Tech’s mold specialists, we courageously tackle complex mold structures and processes. To this end, we have formed a professional mold project team, a mold technology group, a dedicated mold design team, and a process research group.

To ensure a thorough understanding of our clients’ requirements during the manufacturing process and to better serve them, we have set up a specialized mold inspection and acceptance team. This team is responsible for examining mold quality, verifying compliance with client specifications, confirming the completeness of mold documentation, and checking that mold transfer information is prepared according to requirements, including aspects such as appearance, certificates, photographs, and more. These measures provide data support for after-sales services.