– Services

─ Insert Molding

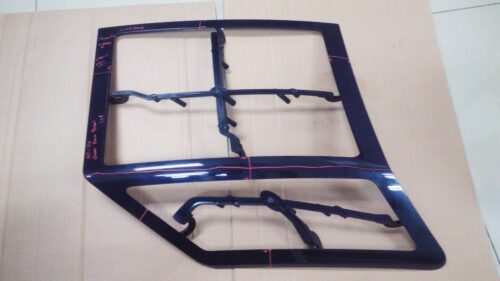

Mold design&build – design for mold efficiency, longevity and performance

Part design-understanding the product application, intended market and performance, end use objectives and use environment.

OUR SERVICES

EngineeringWith over two decades of service in the mold industry, CY Mold Tech’s seasoned engineering team, through years of dedication, is committed to serving our clients. Leveraging professional DFM (Design for Manufacturing) analysis, we optimize products, streamline mold structures, and reduce mold costs.

OUR SERVICES

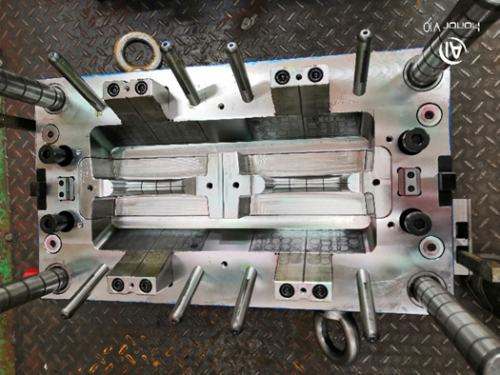

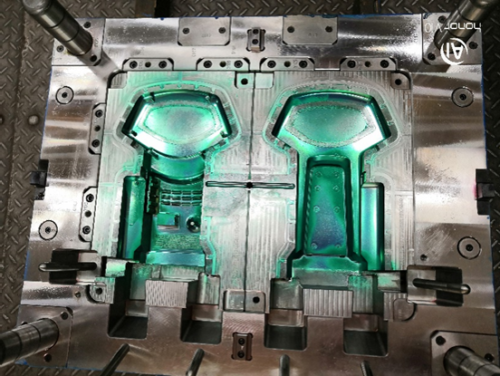

Injection MoldAdhering to customers’ mold standards, technical requirements, and product characteristics, our tooling technology team prepares DFM reports to enhance product designs, simplify mold structures, and economize on mold costs. They scrutinize the rationality of mold designs concerning client-specific injection machine compatibility, including aspects like plate thickness, machining process optimization.

OUR SERVICES

Trail out –SPIEmploying scientific injection molding methodologies, we validate the stability and reliability of molds. Trials are conducted adhering to material property sheets, with customer standards guiding the inspection and acceptance process. We optimize injection molding cycle times, ensuring appropriate holding pressure durations and cooling times.

OUR SERVICES

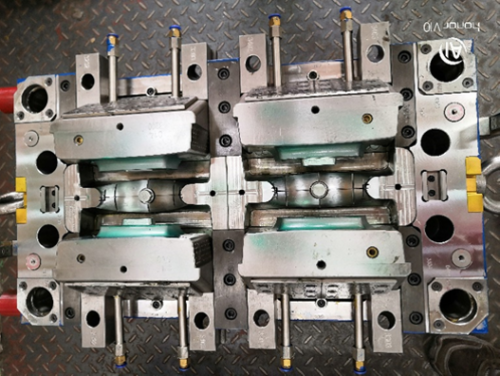

Precision ComponentsIn line with customer mold standards, material properties, and the unique features of mold structures, each component necessitates its tailored machining process. To ascertain the precision of these processes, our process engineers assume responsibility for every part’s machining methodology, creating process sheets for each and overseeing production until completion.